There has been so much debate about all aspects of face coverings.

It is clear that a well fitting mask that follows the contours of the face and securely covers the nose and mouth is best.

As a textile design graduate (many years ago) I have some knowledge of textile properties and fabric construction, both important factors in creating the effective barrier desirable for cloth face masks.

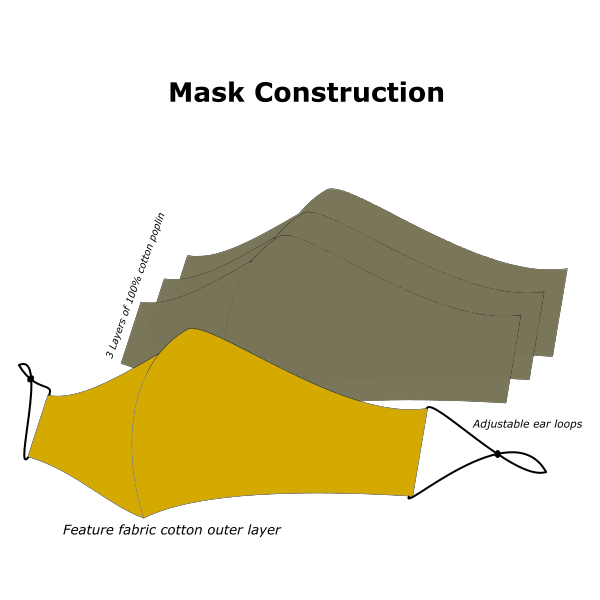

Masks made using multiple layers of tightly woven, breathable, cotton fabric have repeatedly done well in independent testing and appear high up the recommendations for most effective face coverings.

Here’s a link to recent advice from the World Health Organization

Our print and Damask masks are made with 4 layers of 100% cotton fabric, including 3 lining layers of high thread count cotton poplin. Adjustable ear loops add to the personalised fit of our masks.

Our 100% cotton denim masks have 2 additional lining layers. Denim is a very tightly woven twill weave which is one the most dense and closely woven fabrics. We use premium quality 10oz denims in black and deep indigo and these have been amongst our best sellers.

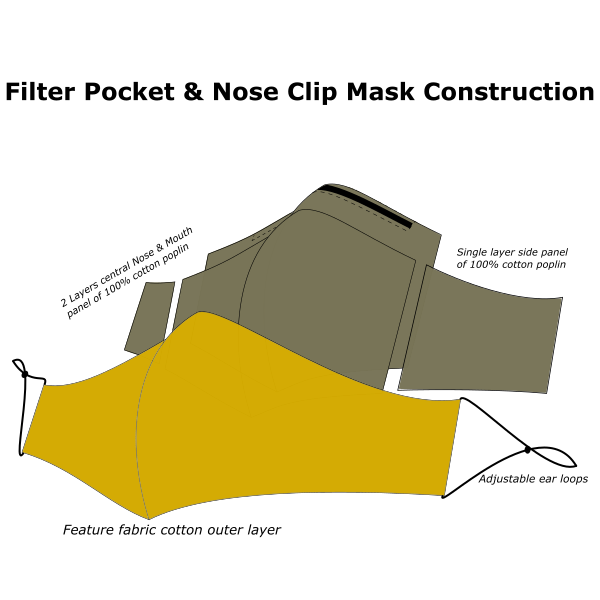

NEW – filer pocket and nose clip masks

Using the same contoured shaping as our original design these masks include an internal pocket to insert a filter and also a concealed insert for an aluminium nose clip. The nose and mouth are protected by 3 layers of 100% cotton, so this mask can also be used without filters.

All of our masks are made to order and available in a range of sizes. If you have any specific requests or requirements please do drop us a line and we’ll see what we can do

#staysafe